The widespread application of cast titanium alloys in the valve industry

Jan 07, 2026

Titanium alloys have become a vital component in various industries due to their distinct performance advantages in the field of materials science. Cast titanium alloys, a significant component of the titanium alloy category, are produced through casting processes and exhibit considerable application potential in valves and numerous other industries.

Cast titanium alloys offer a number of key advantages over traditional alloy materials. Their low density allows for effective weight reduction while maintaining strength; high specific strength means that titanium alloys can withstand greater loads at the same weight; excellent corrosion resistance ensures stability in various harsh environments; and titanium alloys maintain good performance under both high and low temperatures. These characteristics have led to the widespread application of titanium alloys in petrochemicals, marine environments, biomedicine, aerospace, the automotive industry, and shipbuilding, among other fields. As the demands for material performance continue to increase across various industries, the advantages of titanium alloys are becoming increasingly prominent, making them a key factor in driving technological progress in these industries.

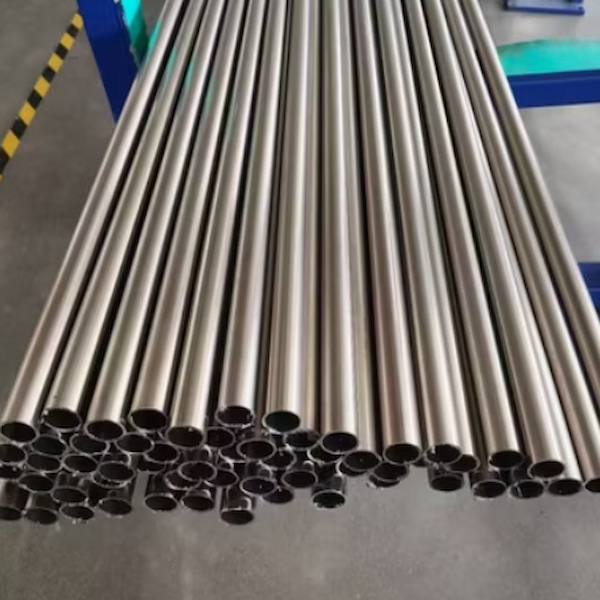

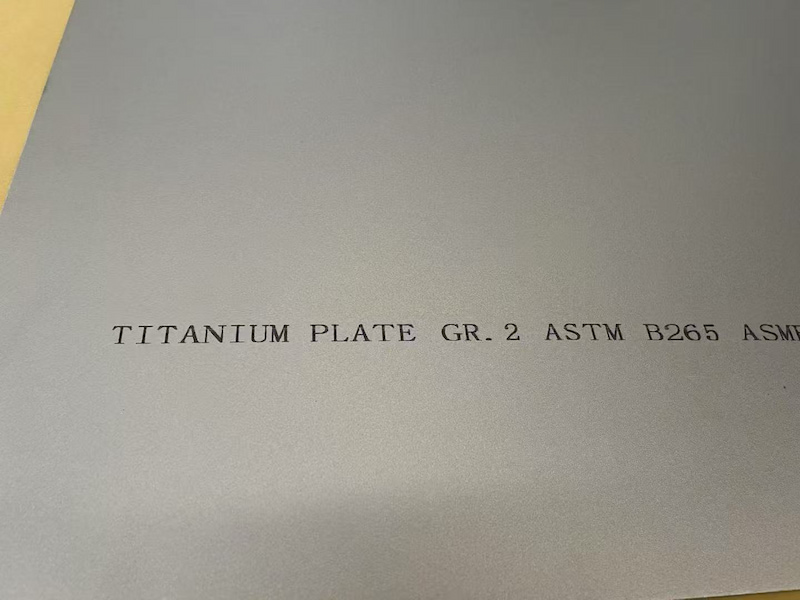

Cast titanium alloys are products manufactured using a casting process to create specific shapes. The TC4 (Ti-6Al-4V) alloy is the most widely used. This alloy demonstrates consistent processing performance and exhibits exceptional strength and fracture toughness below 350°C. Titanium alloys can be classified based on composition as α, β, and α+β types. According to strength, they are categorized as medium-strength or high-strength. Based on operating temperature, titanium alloys are divided into low-temperature (less than or equal to room temperature), medium-temperature (400°C), high-temperature (greater than or equal to 500°C), and combustion-resistant categories. This diverse classification fully reflects the wide applicability of cast titanium alloys. For instance, the common TC4 cast titanium alloy contains between 5.5% and 6.75% Al, and between 3.5% and 4.5% V, with the remainder being Ti. Its tensile strength can reach 895 MPa, and its yield strength is 825 MPa, with mechanical properties similar to medium- and high-strength steel. This allows it to partially replace steel in certain applications. Its density of 4.4 g/cm³ is significantly lower than steel, making it an ideal material for reducing equipment weight. At the same time, it maintains the superior corrosion resistance of titanium alloys, which is unmatched by steel. Consequently, in industrial production scenarios where weight reduction is a priority, opting for a suitable cast titanium alloy can effectively minimize product weight while ensuring consistent performance. This performance advantage confers upon cast titanium alloys an irreplaceable position in fields characterized by extremely high demands on weight and corrosion resistance.

Marine Titanium Valves: The Chinese economy has seen rapid development, resulting in increased demand for valves in the market. The valve industry has experienced significant advancements. Valves are typically composed of multiple components, including the valve body, valve cover, valve disc, and valve stem. Each component has distinct material requirements. Common valve materials include gray cast iron, ductile iron, alloy steel, and copper alloys. However, in some harsh working environments and complex and special working conditions, conventional valve materials are difficult to meet production and scientific research needs. Titanium and cast titanium alloys have garnered attention due to their superior performance, and titanium valves have developed to a certain extent. As the marine economy continues to expand, the performance requirements for marine valves are increasing. The development of titanium valves aligns with this trend, making it a suitable solution for a variety of applications. The working environment of seawater piping systems is harsh, and the performance of marine valves directly affects the safety of the piping system. Since the 1960s, Russia has been a leader in the research and development of advanced titanium alloys for marine applications, with a focus on military ship piping systems. This initiative has led to the creation of a diverse range of titanium alloy valves, showcasing Russia's expertise in the field. Concurrently, civilian ship piping systems began incorporating titanium valves. In comparison with materials such as copper alloys and steel, the use of cast titanium alloys significantly improves the reliability of the valve's structural strength and corrosion resistance, and greatly extends its service life, from the original 2-5 years to more than twice that.

Aerospace Titanium Valves: In the aerospace industry, cast titanium alloys demonstrate exceptional performance due to their high heat resistance and strength. In the 1960s, American aviation pioneered the use of titanium castings. Following a period of research from 1972 onward, the application of cast titanium alloys to aircraft was officially approved, including the Boeing 757, 767, and 777 models. Titanium alloy castings were used extensively in static structures and began to be used in critical piping system valve control. Common valves include safety valves and check valves. The application of titanium alloys has been shown to reduce aircraft manufacturing costs while increasing safety and reliability. Titanium alloys, which weigh approximately 60% of steel of equivalent strength, have been used extensively in aircraft manufacturing due to their low density. This has led to the development of aircraft with high strength and lightweight designs. As aerospace technology continues to advance, the demands on materials are becoming more exacting. This creates significant opportunities to leverage the advantages of cast titanium alloys. At present, aerospace valves find primary application in pneumatic, hydraulic, fuel, and lubrication control systems. They are well-suited for environments requiring corrosion resistance and high temperatures. These components are essential for the operation of spacecraft and engines. Traditional valves often require periodic replacement or fail to meet requirements. However, with the rapid expansion of the aerospace valve market, titanium valves are gaining an increasing share due to their superior performance.

Titanium Valves in the Chemical Industry: Chemical valves are typically used in harsh environments involving high temperatures, high pressures, corrosion, and large pressure differentials, making material selection crucial. Early materials primarily consisted of carbon steel and stainless steel, but these materials were prone to corrosion over time, necessitating replacement and maintenance. The development of cast titanium alloy technology and the subsequent discovery of its superior properties have led to the increased utilization of titanium valves in the chemical industry. The advent of cast titanium alloys has introduced a new, high-quality option for valve material selection in the chemical industry. For instance, the production of purified terephthalic acid (PTA) in the chemical fiber industry involves the use of acetic acid and hydrobromic acid, which are highly corrosive substances. The project requires nearly 8,000 valves, and the types are numerous and complex. Titanium valves have become the preferred option due to their enhanced reliability and safety. In the field of urea synthesis, traditional valves have a limited lifespan. Some fertilizer plants have tried using titanium high-pressure check valves and insulated globe valves for the inlet and outlet of urea synthesis towers. These valves have a service life of more than two years, demonstrating good corrosion resistance and reducing valve replacement frequency and operating costs.

Titanium and its alloys possess superior properties, making them ideal substitutes for materials such as steel. In addition, titanium resources are abundant, and as such, have attracted the attention of numerous researchers. Despite the present challenges in the extraction, smelting, and processing of titanium, both the valve industry and the titanium industry are vibrant and rapidly developing sectors. Advancements in stable titanium mining and production technologies, as well as the introduction and refinement of new processes, will make the application of cast titanium alloys and castings in the valve industry more mature and scalable. There will also be broad application prospects in other industries.

Network Supported

Network Supported