Why has the titanium plate become the "universal card" of cutting-edge fields?

May 28, 2025

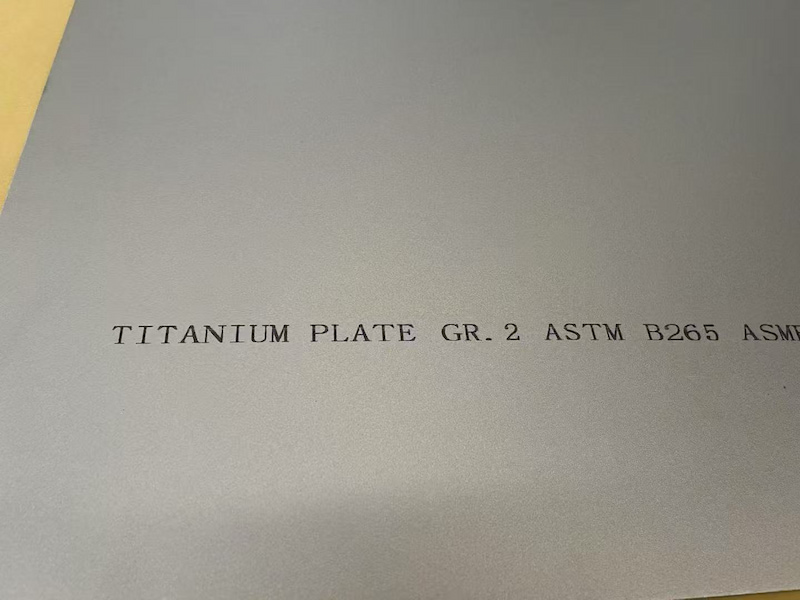

Titanium alloy plates have swept the material world with their light weight, high strength (density of 4.51 g/cm³ and strength up to twice that of steel), and extreme environmental adaptability (-253°C to 600°C stable operation and a seawater corrosion rate of less than 0.001 mm/year). More critical is its triple-core advantage:

First, biocompatibility: the osteointegration rate of medical titanium plates exceeds 95%, and the Ti-6Al-7Nb alloy eliminates vanadium toxicity and reduces the wear rate by 60%.

Performance adjustability: Alloying allows for precise matching of needs. For example, the resistance of a TA10 titanium plate to concentrated hydrochloric acid corrosion is 50 times greater than that of stainless steel.

Process extensibility: It can be used for traditional rolling, explosion compositing, and 3D printing. It can be adapted for use with ultra-thin foils (0.089 mm) and wide, thick plates (3,300 mm).

Titanium alloy application areas:1. Aerospace: Effectively enhances satellite load and is resistant to deep cold environments.2. Deep-Sea and Nuclear Energy: Withstands high-intensity water pressure and is highly corrosion-resistant.3. Medical and healthcare: The titanium alloy bone plate fits with high precision and has strong bending fatigue resistance and a short fusion cycle.4. Chemical ships: corrosion resistance, extended equipment maintenance cycles, and a service life far beyond that of other materials.

Titanium alloy plate has become a “universal medium” for high-end manufacturing due to its plasticity and environmental adaptability, as evidenced by its use in everything from deep-submersible spherical shells to folding screen hinges.

Network Supported

Network Supported