The high-end manufacturing field has put forward multi-dimensional and stringent requirements on the comprehensive performance of structural materials due to the rapid development of modern industry. In cutting-edge fields such as aerospace and medical device research and development, there is a desire to achieve high strength and light weight as well as key properties such as corrosion and creep resistance. TC4 titanium alloy (Ti-6Al-4V), a typical α+β dual-phase alloy, has excellent specific strength, thermal stability, fatigue resistance, and corrosion resistance. These properties make it a material that meets the above requirements. However, this material presents challenges in the precision manufacturing process. Due to its high strength and toughness, low thermal conductivity, and low elastic modulus, work hardening occurs easily during cutting. This leads to a sharp increase in cutting temperature, which affects forming accuracy. Pores and thermal cracks easily form during welding, and the welded area easily oxidizes at high temperatures.

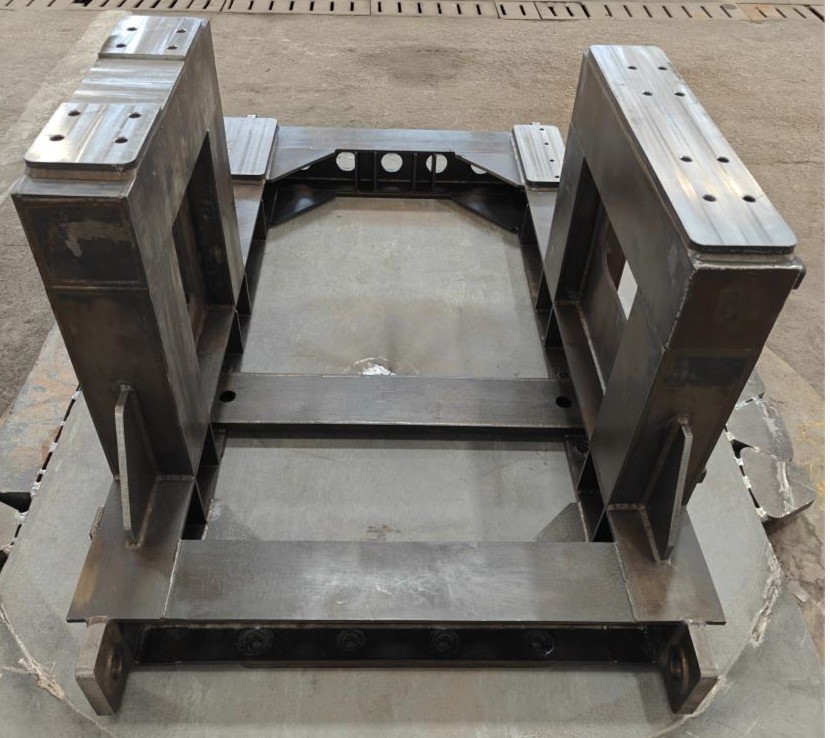

Recently, Nanjing Baotai was commissioned by customers to manufacture a batch of TC4 titanium alloy cable winch bases. This batch of structural parts is made of titanium alloy TC4 and has a maximum length of 1930 mm, a maximum width of 1160 mm, and a height of 800 mm.

The challenges in producing this batch of titanium alloys are:

1. The titanium alloy base has a complex structure, and there are strict tolerance requirements in many places. The minimum tolerance range is 0.1 mm, and there are requirements for multiple geometric tolerances, concentricity, etc.

2. Titanium easily reacts with gases such as oxygen, nitrogen, and hydrogen at high temperatures, forming brittle compounds that result in weld embrittlement and decreased plastic toughness. The high solubility of molten titanium in hydrogen and oxygen, as well as the rapid precipitation during solidification, can lead to the formation of pores. These pores create stress concentration points in titanium alloy welds, thereby reducing their quality.

3. The thermal conductivity of titanium alloys is only one-quarter that of steel. Local high temperatures during welding lead to significant temperature gradients and deformation. Titanium alloys react easily with oxygen and nitrogen at high temperatures. Tooling must be designed in coordination with the gas protection system to prevent oxidation embrittlement. The elastic modulus of titanium alloys is relatively low, and the base's large welding area results in significant residual deformation after welding, easily causing the workpiece's shape and size to change.

After many rounds of discussions about the process and technical tests, the Baotai technical team determined the main technical aspects of manufacturing and processing the TC4 titanium alloy cable winch base. They analyzed the three-dimensional model, optimized the machining process, designed the tooling, accurately controlled the processing speed, and strengthened the cooling measures to ensure the accuracy of the internal and external processing. Optimizing the welding process effectively controls deformation and dimensional changes after welding and significantly reduces defects generated during the welding process.

The successful manufacturing of the titanium alloy cable winch base is a significant step forward in science, technology, and innovation. As science and technology continue to advance and production technology continues to improve, the application scope of titanium alloys will expand to more key areas. As new technologies are developed, the market for titanium alloys will grow, and we will be able to meet the needs of different industries for high-performance materials. Guided by market demand and customer satisfaction, we make full use of our technical equipment's advantages and constantly pursue improvement and innovation to enhance the company's technical strength and market competitiveness.

Friendly Link :

diyiye.com

Copyright @ 2026 Nanjing Baotai Special Materials Co., Ltd. All Rights Reserved.  Network Supported

Network Supported