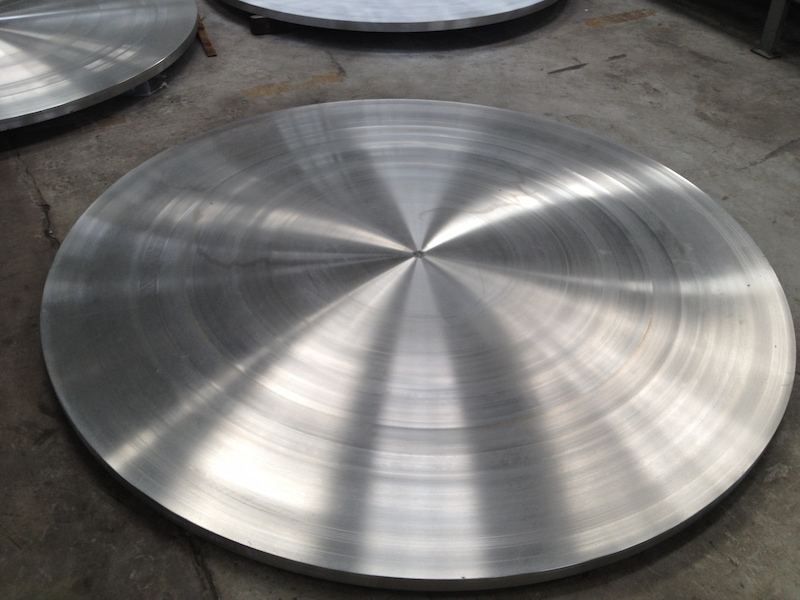

Tube sheet cladding is a protective coating applied to the tube sheets of heat exchangers and similar equipment. Tube sheets are key components that hold tubes in place and separate different fluid flows within heat exchangers. Depending on the operating conditions of the equipment, the cladding is usually made of materials that are resistant to corrosion, erosion, and other forms of wear.

Chemical producers use shell and tube heat exchangers very commonly. However, the tubes in these heat exchangers must be connected to tube plates, and the strength of these connections and their sealing performance are crucial. If leakage occurs around the combination part due to corrosion, temperature, pressure, or temperature fluctuations during use, it is crucial to select a high-quality tube sheet.

For Shell and Tube Heat Exchangers

When a single material cannot withstand medium corrosion, the heat exchanger must use a bimetallic tube sheet, also known as a composite tube sheet. Even if there is only medium corrosion, using a composite tube plate is more economical than using a tube plate made of precious metals. Composite tube sheets perform even better. The bonding performance of a composite tube sheet is good. Composite tube sheets are the preferred material for heat exchangers.

Specialized metals for composite tube sheets include stainless steel and carbon steel, nickel and nickel-based alloys and carbon steel, and so on.

Friendly Link :

diyiye.com

Copyright @ 2026 Nanjing Baotai Special Materials Co., Ltd. All Rights Reserved.  Network Supported

Network Supported