Titanium is a high-quality piping material widely used in many industries due to its strength, density and corrosion resistance. Due to its light weight and corrosion resistance, titanium often outperforms competing materials such as stainless steel or high temperature alloys.

Titanium spools are designed for chemical processing and are supplied with all components such as flanges and valves to complete the assembly.

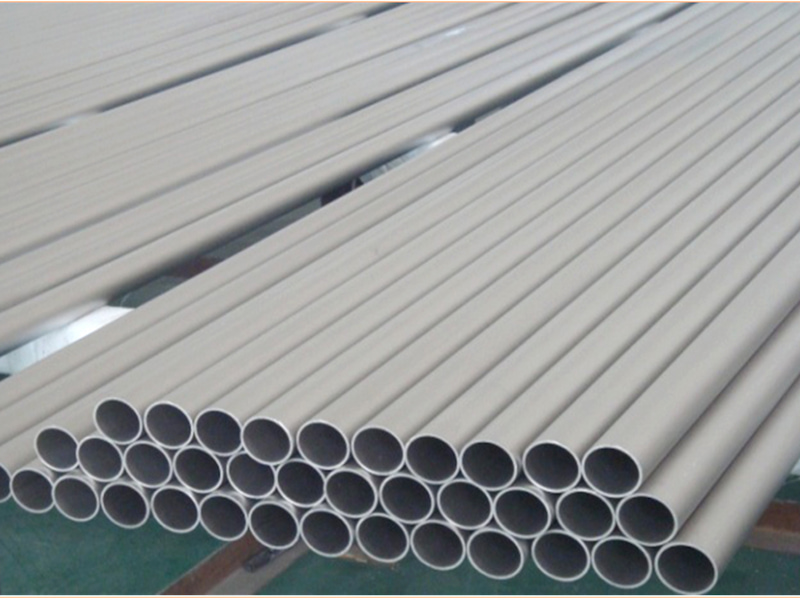

There are many types of titanium tubing, and these types can be used to determine the suitability of each type. Depending on the process, titanium tubing can be categorized into two types: welded tubing and seamless tubing.

○Seamless Titanium Tubing

○Welded Titanium Tubing

Seamless Titanium Tubing

As the name suggests, seamless titanium tubing has no seams, joints, or welds in its body. As a result, they are able to withstand the pressure of precision liquids and gases because they are strong in all directions. While welded tubes are available in a wider selection of sizes and shapes, seamless titanium tubes typically have higher strength and pressure resistance.

Welded Titanium Tubing

Welding is used in the manufacturing of titanium tubing to extend the length of the tube or to keep its shape intact. The oxide layer must be removed before welding titanium tubing, just as it is with aluminum and stainless steel.

Friendly Link :

diyiye.com

Copyright @ 2026 Nanjing Baotai Special Materials Co., Ltd. All Rights Reserved.  Network Supported

Network Supported