Nickel-chromium alloy INCONEL is an austenitic, heat-resistant superalloy with nickel as its main component. It is an oxidation- and corrosion-resistant material that exhibits ultra-high strength, fatigue resistance, oxidation resistance, chemical stability, good weldability, and ease of processing at temperatures up to 1093°C. INCONEL is also an oxidizing, corrosion-resistant material that exhibits high strength, fatigue resistance, oxidation resistance, chemical stability, good weldability, and ease of processing.

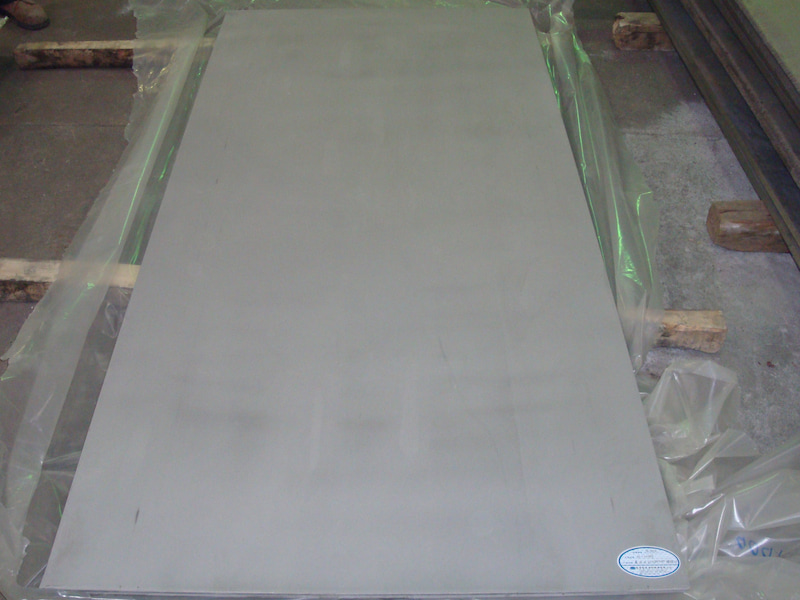

Corrosion-Resistant Inconel Nickel-Chromium Plate

Inconel 625

is a nickel-chromium-based solid-strengthened, deformation-resistant, high-temperature alloy. Molybdenum and niobium are the main strengthening elements in the alloy. It is typically used at temperatures up to 950°C. Inconel 625 exhibits excellent tensile and fatigue properties over a wide temperature range. It is also highly machinable and weldable. The alloy exhibits excellent corrosion, oxidation, and stress corrosion resistance in salt spray environments.

It is commonly used in gas turbine engines for piping systems, jet engine exhaust systems, engine thrust reversers, and turbine cowling rings. It is also used in nuclear power equipment for reactor core and control rod components and waste reprocessing equipment. Additionally, it is used in aerospace engines and is particularly suitable for seawater contact and applications requiring high mechanical properties. Other applications include air pollution control (chimney liners, dampers, and flue gas desulfurization components), offshore oil and gas production (flare gas stacks, piping systems, riser jacketing, and sour gas piping), and petroleum refining (flare gas stacks). Other applications include steam piping bellows for marine services, naval vessel exhaust systems, and submarine auxiliary propulsion systems.

Friendly Link :

diyiye.com

Copyright @ 2026 Nanjing Baotai Special Materials Co., Ltd. All Rights Reserved.  Network Supported

Network Supported