This is the ultimate solution for electrolytic copper foil cathode and anode drums. Its exceptional conductivity, unmatched corrosion resistance and extended service life enable the production of high-quality foil.

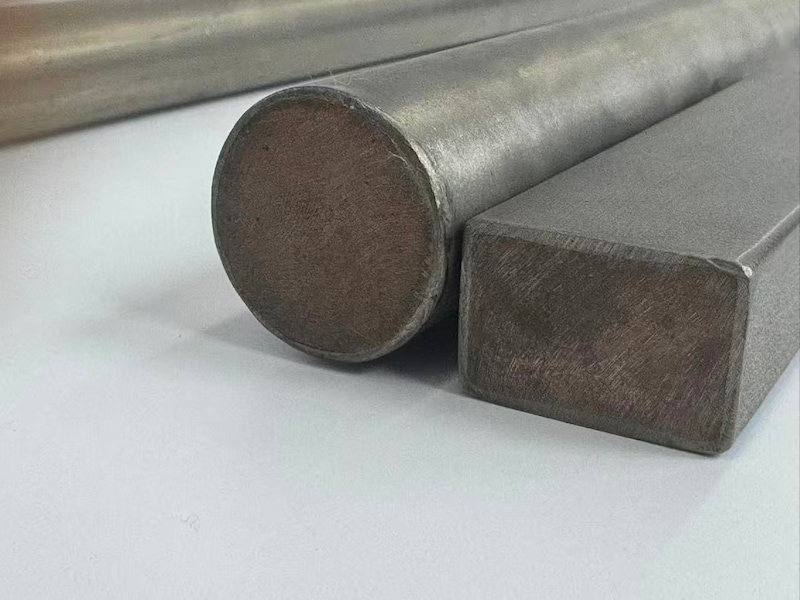

Titanium Clad Copper Rod Bars for Electrowinning Industry

Our Titanium-Copper Bimetallic Composite Rods are specifically engineered for use in critical applications such as cathode and anode drum shafts in the electrolytic copper foil industry. They set new standards for performance and durability. Seamlessly bonding high-strength titanium with highly conductive copper has created a component that overcomes the limitations of traditional materials, ensuring maximum efficiency, minimal downtime and exceptional foil quality.

Key Advantages and Benefits for Titanium Clad Copper Rod Bars

Unmatched corrosion resistance:

Titanium cladding is highly resistant to corrosive electrolytes, such as sulfuric acid. This prevents pitting, scaling and electrochemical corrosion, thereby safeguarding the core copper conductor and ensuring stable performance.

Superior electrical conductivity:

Oxygen-free copper cores deliver exceptional current distribution across the entire drum surface. This results in uniform foil thickness, reduced energy consumption and high-speed deposition.

Exceptional Bond Strength:

Our proprietary explosive or metallurgical bonding process creates a permanent bond between titanium and copper. This bond can withstand extreme thermal cycling and mechanical stress without delamination.

Extended service life and return on investment:

It significantly reduces maintenance costs, downtime and the frequency of roller replacement. Compared to traditional copper or coated shafts, titanium-copper composite rods offer a substantially longer service life and deliver an exceptional return on investment.

| Product Name | GR5 fishing rod polished ASTM B348 straight 6mm titanium rod |

| Material | Pure titanium and Titanium alloy |

| Titanium Grade |

GR1/GR2/GR3/Gr4/GR5/GR7/GR9/GR12/Gr5Eli/Gr23 |

|

Diameter |

10mm - 50mm (Custom sizes available upon request) |

| Length | 50mm-7500mm (Custom sizes available upon request) |

| Cladding Thickness | 3mm - 10mm (Standard, customizable based on application) |

| Bonding Quality | 100% ULTRASONIC inspection to ensure zero delamination. |

| Electrical Conductivity | ≥ 98% IACS (Core Copper) |

| Surface Finish | Machined and polished to customer specifications (e.g., Ra ≤ 0.8 µm for sealing surfaces). |

| Material Milling Certificate | According to. EN 10204.3.1 |

| Standard | ASTM B348/ASME SB348, ASTMF67, ASTM F136, ISO-5832-2(3),AMS 4928 etc. |

Friendly Link :

diyiye.com

Copyright @ 2026 Nanjing Baotai Special Materials Co., Ltd. All Rights Reserved.  Network Supported

Network Supported