Incoloy 800 and Incoloy 825 are nickel-iron-chromium alloys renowned for their exceptional resistance to high temperatures, oxidation, carburization, and a wide range of corrosive media. Our plates are the best choice for critical applications in demanding environments where standard stainless steels don't meet the required standards.

These alloys are the strongest and most durable, making them the obvious choice for chemical processing, power generation, and the oil and gas industries.

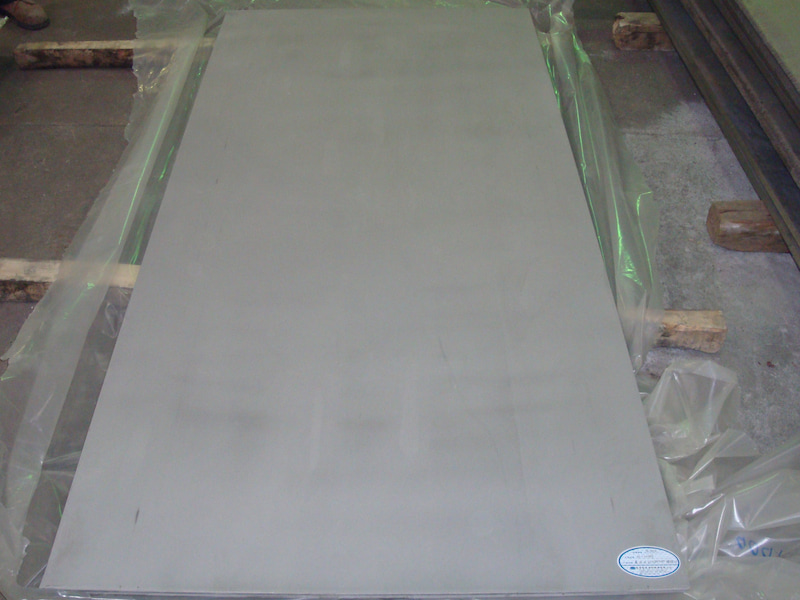

ASTM ASME GB Nickel Alloy N08800 825 Incoloy Plate

Our plates meet and exceed the requirements of the following specifications.

ASTM B409 is the standard specification for nickel-iron-chromium alloy plates, sheets and strips.

ASME SB-409 is the definitive code for boilers and pressure vessels.

GB/T 15007 is the Chinese Standard for Nickel-Based Corrosion-Resistant Alloys.

Others: The specifications are EN 10095, UNS N08800 and UNS N08825.

Certification: All materials are accompanied by certificates of conformity and provide complete traceability.

Superior Corrosion Resistance: Highly resistant to oxidation, carburization, sulfidation, and chloride stress corrosion cracking. Alloy 825 exhibits outstanding resistance to reducing acid corrosion.

High-Temperature Strength: Maintains excellent mechanical properties and structural stability at elevated temperatures (Alloy 800 up to 1100°F / 600°C, Alloys 800H/800HT up to higher temperatures).

Versatile Material Properties: This nickel-chromium-iron alloy is perfectly balanced, offering unparalleled protection in oxidising and reducing environments.

Superior Fabrication Properties: It is easily formed, welded, and machined using standard nickel alloy processes.

Quality Certification: We provide complete traceability and factory test reports (MTR), confirming compliance with ASTM, ASME, and GB standards.

Our nickel alloys N08800 and N08825 plates are perfect for critical applications.

Chemical Processing: Reactors, heat exchangers, distillation columns and piping systems handling acids and alkalis are all essential components.

Power Generation: We specialise in superheater and reheater tubes, heat exchangers and boiler components for fossil fuel and nuclear power plants.

Oil and Gas: Our specialities include downhole tubing, wellhead components and process equipment in sour gas environments.

Industrial Heating: Radiant tubes are used in heat treatment furnaces, muffle furnaces, distillers and basket assemblies.

Pollution Control: Scrubbers, piping, and flue gas desulfurization systems.

Nuclear Fuel Processing: Components.

Friendly Link :

diyiye.com

Copyright @ 2026 Nanjing Baotai Special Materials Co., Ltd. All Rights Reserved.  Network Supported

Network Supported