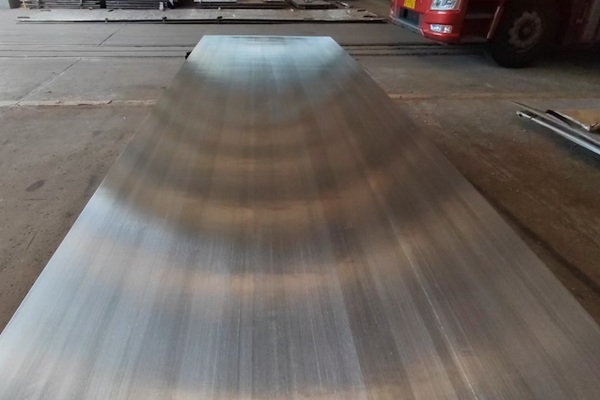

Zirconium-titanium-steel clad plate is an advanced layered composite material specifically engineered for demanding pressure vessel applications in corrosive environments. This innovative material combines the exceptional corrosion resistance of zirconium and titanium with the structural strength of carbon steel or low-alloy steel. Manufactured using explosion welding or explosion rolling composite technology, our clad plates comply with stringent ASME standards while delivering cost-effective solutions for the chemical, nuclear power, and marine industries.

Zirconium-Titanium-Steel Clad Plate for Pressure Vessels

Zirconium-Titanium-Steel Clad Plate for Pressure Vessels

Cladding layers: Zirconium (Grade R60702/R60703) and/or titanium (Grade 1/Grade 2)

Base material: Carbon steel, low-alloy steel or stainless steel

Bonding method: Explosive welding or explosive rolling composite technology

Interface strength: Shear strength ≥ 140 MPa (exceeding standard requirements)

Maximum available size: Up to 15 m² for single plates

Total thickness range: 8 mm to 150 mm

| Property | Zirconium Clad Side | Titanium Clad Side | Steel Base Layer |

| Yield Strength | ≥170 MPa | ≥275 MPa | Varies by grade |

| Tensile Strength | ≥380 MPa | ≥420 MPa | Varies by grade |

| Elongation | ≥20% | ≥20% | Varies by grade |

| Shear Strength | ≥140 MPa | ≥140 MPa | / |

- Acetic acid production equipment (e.g. reactors, columns and heat exchangers)

- PVC production facilities (chlorine processing components).

- Pharmaceutical manufacturing (containment of corrosive media)

- Fine chemical processing (reaction vessels and storage tanks).

Zirconium-titanium-steel composite plates provide exceptional resistance to acetic acid, bromides and chlorides at elevated temperatures in acetic acid towers, significantly outperforming stainless steels. This material's reliability has been demonstrated in projects for major chemical companies, including Huayi Energy and Hengli Petrochemical.

Multicomponent silicon production: Silver-steel clad plates for reduction furnaces

Marine engineering: Offshore platform components and shipboard chemical containers

Environmental protection: Flue gas desulfurization systems and waste treatment equipment

New energy: Equipment for battery material production and hydrogen processing

Our proprietary explosion bonding technology creates metallurgical bonds with uniform interface waves, ensuring optimal stress distribution and eliminating delamination risks. The advanced manufacturing process includes:

Automated surface treatment for optimal bonding conditions

Post-bonding heat treatment that reduces interface hardness by over 20%

Advanced non-destructive testing including ultrasonic imaging and residual stress measurement

Every batch undergoes rigorous testing including:

Ultrasonic inspection of the bonding interface per ASTM A578

Mechanical property testing including shear strength, bending, and impact tests

Corrosion testing in simulated service environments

Dimensions and visual inspection to ensure surface quality

While initial costs are higher than conventional materials, our clad plates offer significant life-cycle savings through:

Extended equipment lifespan (3-5 times longer than stainless steel in corrosive services)

Reduced maintenance downtime

Elimination of lining failures and associated production losses

Lower insurance costs due to enhanced safety performance

Our engineering team provides comprehensive support including:

Material selection guidance for specific corrosive environments

Welding procedure specifications for clad plate fabrication

Design optimization for pressure vessels using composite materials

Failure analysis and troubleshooting for existing equipment

For optimal results when fabricating with our clad plates:

Follow specialized welding procedures for transition joints

Employ proper cutting techniques (waterjet, plasma, or mechanical methods)

Apply appropriate heat treatment cycles to preserve interface properties

Utilize qualified NDT methods for quality verification during fabrication

Friendly Link :

diyiye.com

Copyright @ 2026 Nanjing Baotai Special Materials Co., Ltd. All Rights Reserved.  Network Supported

Network Supported